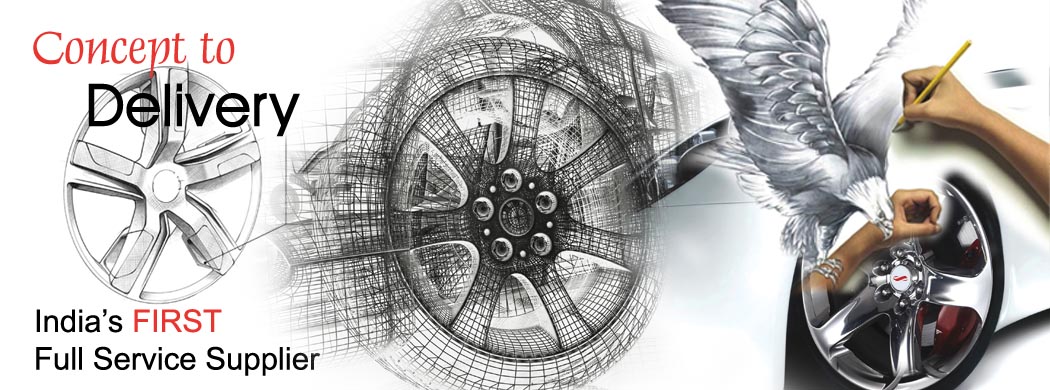

ABOUT US

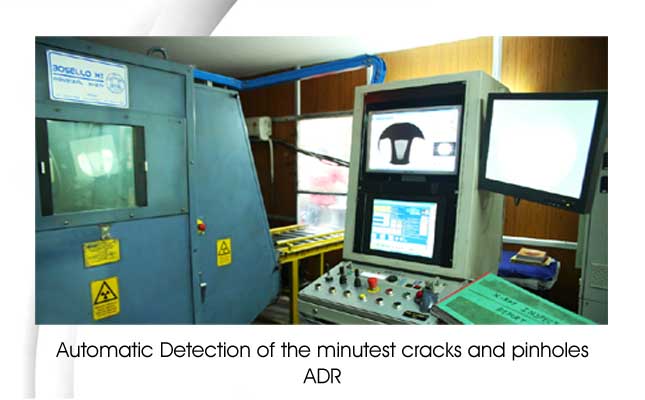

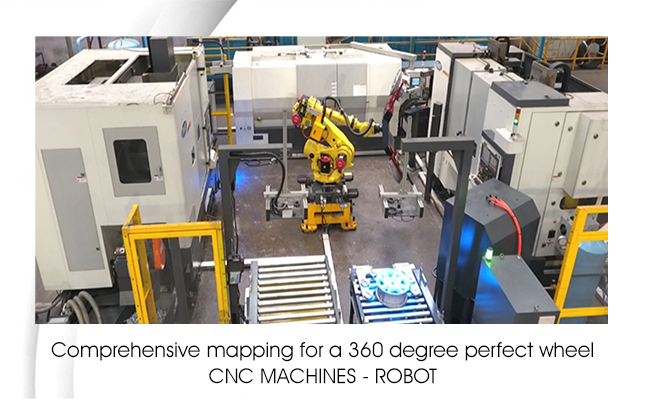

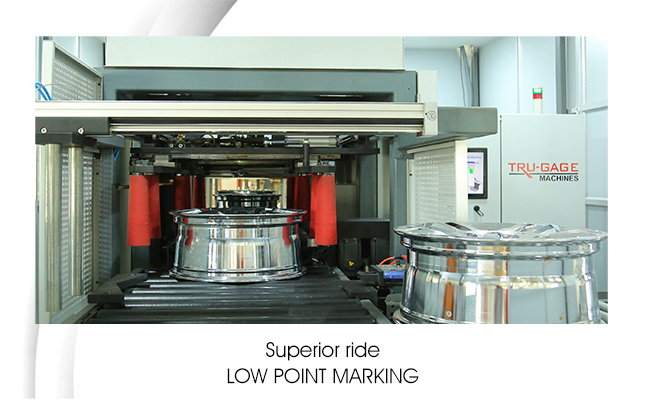

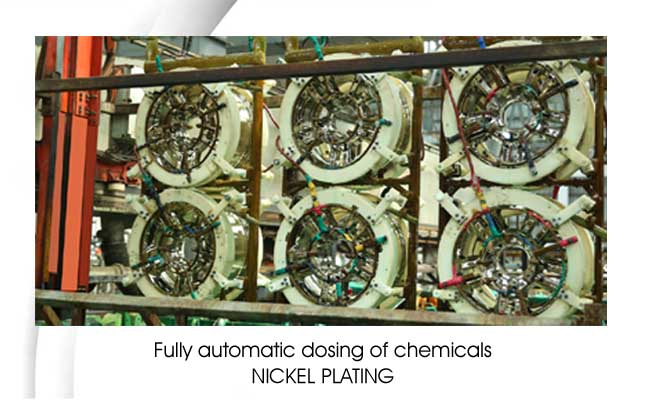

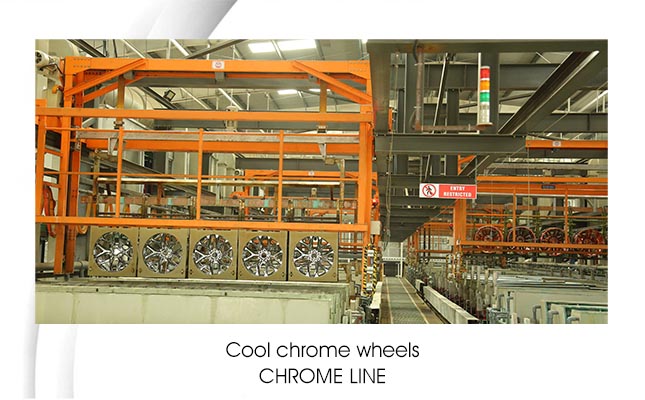

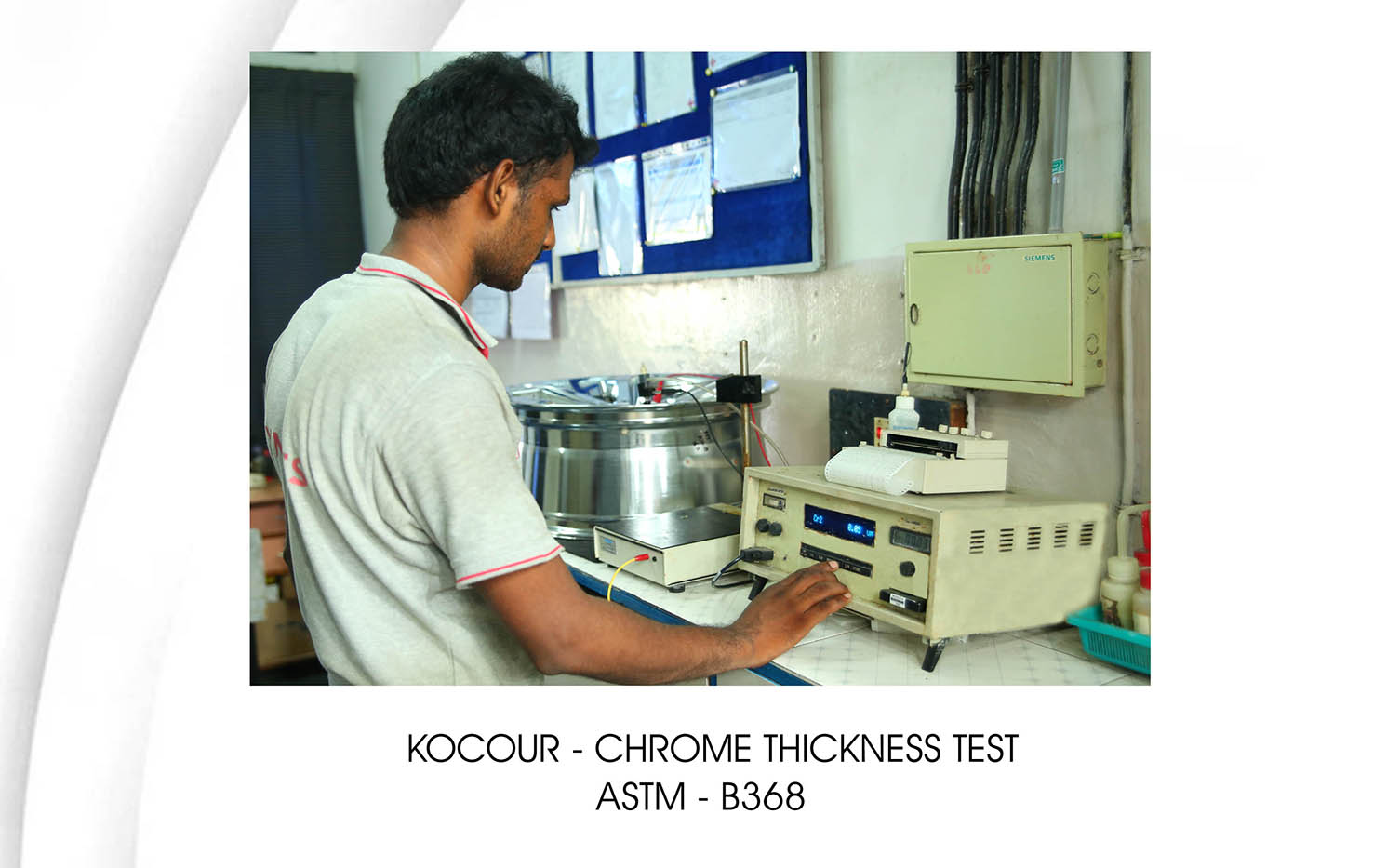

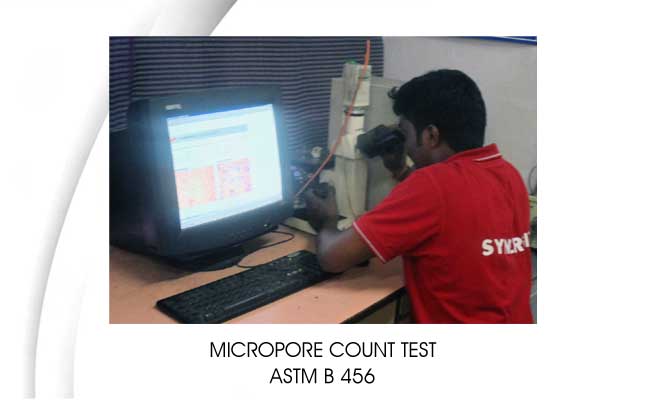

SYNERGIES, the pioneer and leader amongst alloy wheel manufacturers in India, specialises in producing extremely high-precision, high-quality alloy wheels. Since wheels are subject to extreme stresses and lateral forces, they must be perfectly manufactured, else safety is compromised. Our wheels are meticulously crafted to be absolutely porosity-free, air-leak-free, must have extremely close tolerances, and a superb surface finish. Achieving this level of excellence requires absolute and precise control at every step of the casting process - from the composition of the molten metal, the forming, the solidification, to the cooling process, and all downstream finishing processes - CNC machining, multistage electrostatic painting / chrome plating.

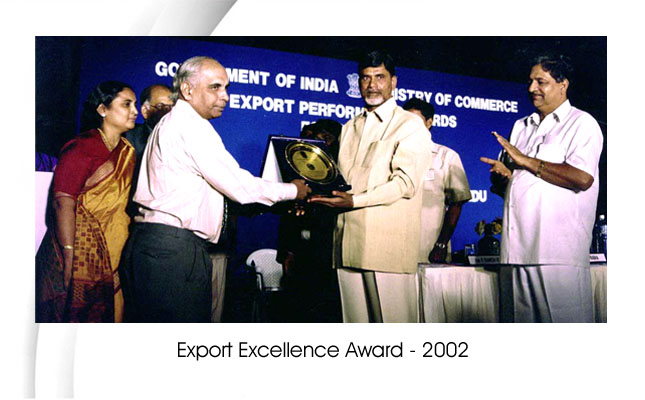

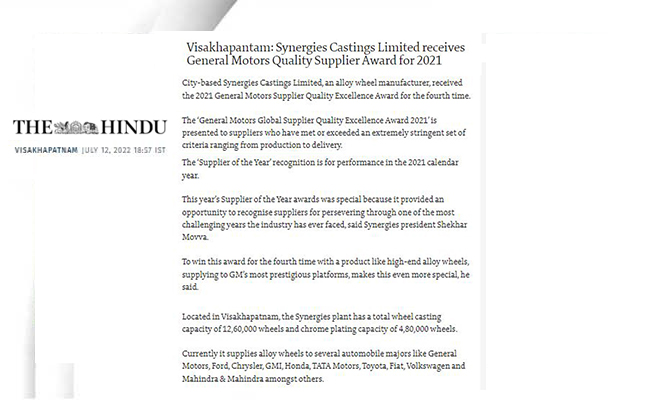

Located in Visakhapatnam, the SYNERGIES plant has a total wheel casting capacity of 1,260,000 wheels and a chrome plating capacity of 360,000 wheels, both benchmarked at an 18” size. The company is certified with IATF 16949, ISO 14001, ISO 45001:2018, ISO 27001:2022, MS 9000, Ford Q1, JWL, VIA, and TUV standards.

SYNERGIES, a precision alloy car wheel manufacturer currently supplies alloy wheels to several major automobile companies, including Stellantis, General Motors, MG Motors, BMW, TATA Motors, and Gulf States Toyota, among others.